Kiln Burning Zone & Cooler is the most important Zones in cement plant. Thus, monitoring of these zones is a mandatory requirement.

The Pyrometer in burning zone does not provide much information about the all operation; it gives only a single measurement value from a small part of the kiln. And, so the readings can be deceptive, if the target area is not optimized.

A Rotary Kiln is one of the most critical plant items in the cement making process. It is often a vital requirement for operators to have a constant view of the kiln’s internal operations on screen in the control room, in order to identify ring build ups, blockages or other upset conditions at an early stage.

Also the view of cooler is important because of formation of clinker. Clinker size can affect the capacity of plant, as well as quality of cement. It can shorten the life of kiln brick and cooler.

Camera is the only solution for both Kiln & Cooler inside view.

We have two types of camera; Normal View & Thermal View Camera

Normal View Camera TFV 750 and TFV750/OV

High-temperature Furnace monitoring systems provide views of burner flames, material alignment and movement, and other process conditions in kiln and coolerto plant engineers and operators in the control room. We use special color camera above 640 lines, pinhole lens and stainless steel came

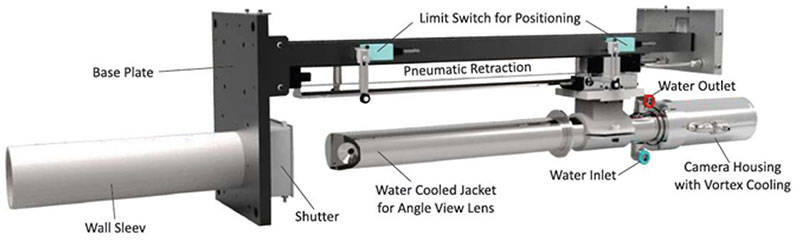

Normal view camera schematic and images of kiln are below:

Normal Camera System

The system has auto-retraction and manual insertion function (for safety of worker). These things are regulated by control panel with the help of PLC and pneumatic system. With this model we are able to view the inside of kiln only.

Normal View Camera Image (inside View of Kiln) Captured From Monitor

Thermal View Camera TE750 and TE750/OV and Advantages

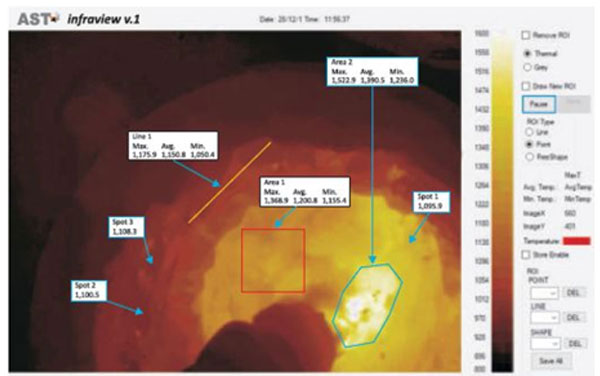

To obtain more detailed process information about the kiln, a more modern approach is to use a short wavelength thermal view camera. Because Temperature monitoring across the manufacturing process is essential to support process efficiency and cement product quality. It can also help to increase the life of the kiln through early detection of refractory issues or insufficiently quenched clinker, which could lead to production stoppages if left unchecked. Monitoring solutions also support safety and emissions control.

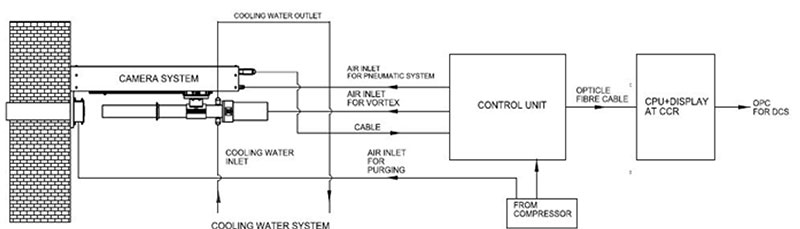

Thermal view camera schematic and kiln view as below.

Thermal Camera System

This camera is very needful demand as per current situation. Because the kiln rotates continuously, the clinker collects on one side. This allows the thermal view camera to be installed under the burner towards the opposite side, providing sighting onto the clinker and flame. The wide-angle image, with high spatial resolution, allows accurate temperature measurements and important information about the process conditions within the burning zone. This camera used in both kiln burning zone and cooler zone.

Thermal View Camera Image (inside View Of Kiln) Captured From Monitor

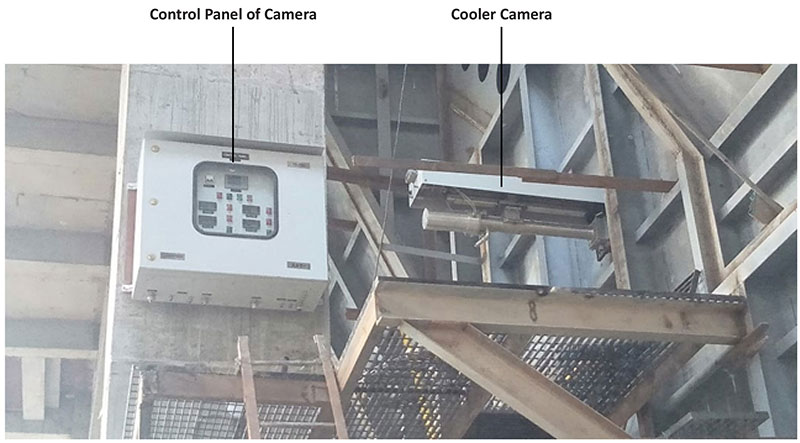

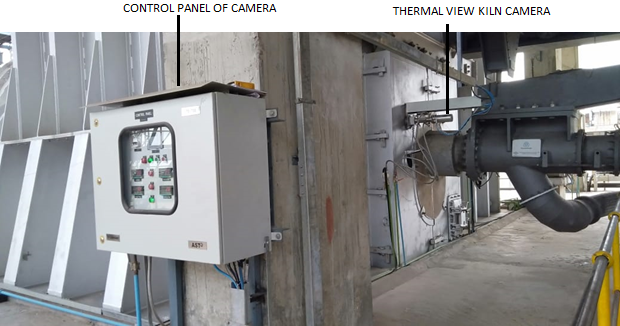

Thermal View Kiln Camera Installation

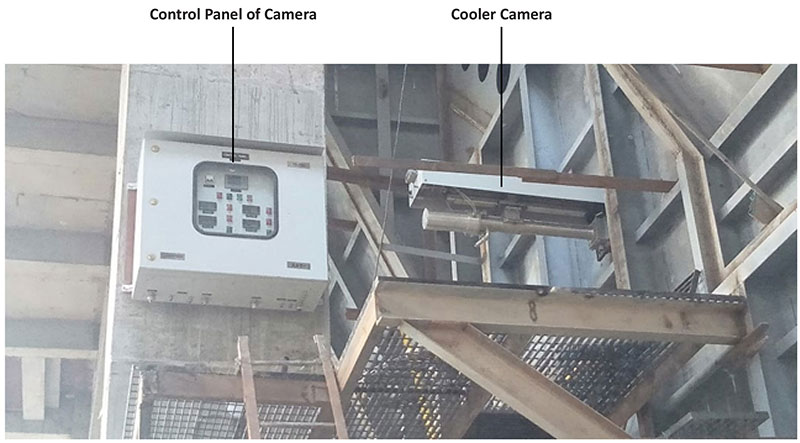

Cooler Camera Installation