What is Reheating Furnace and their use

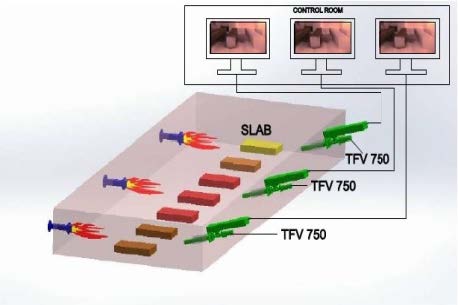

The Reheating Furnace in general is a furnace used in hot rolling mills to heat the raw material like bloom, billet,

slab, ingot, rounds etc to rolling temperature. The reheating furnaces uses oil, gas, electricity, coal as main fuel as

heat source. The process of Temperature control, furnace pressure control can be manual or automatic.

Types Of Reheating Furnaces

The Reheating furnaces are of different types depending upon heating capacity, grade of material and material

shape

Furnaces can be:

- Pusher Type Reheating Furnace

- Rotary Hearth Reheating Furnace

- Walking Beam Reheating Furnace

- Top/Bottom Fired Pusher Reheating Furnace.

What is the Need of Internal Monitoring

We all know that the monitoring plays a crucial role in this complete process. With the help of internal monitoring

of Reheating Furnaces, we improve quality, maintain temperature, reduce heating cost by control of fuel, burner

fire, pressure control etc. Also improve productivity; reduce rejections, decrease production cost. It helps to

monitoring at discharging point to pick up the billets, ingots, slabs by robotic arm. It helps in efficient and

accurate working in extreme high temperature.

Why we need High Temperature Monitoring System for this particular application?

The manual monitoring is not possible in reheating process due to harsh environment, high temperature outside

or inside furnace, negative or positive pressure of furnace. Also manual monitoring is not accurate and

continuous so we use High Temperature Monitoring System for this application.

High Temperature Monitoring System is used in Reheating furnace near Charging & discharging Door.

In rotary hearth furnace angular view Camera system (TFV-1100/OV) is used in different zones & near Charging &

discharging Door.

Site Challenges

- The environment is very harsh, dusty and oily.

- The site ambient temperature is very high up to 70°C or 90°C outside the furnace and around 1200°C inside the

furnace.

Our Model for this Application (TFV-1100)

The TFV-1100 High Temperature Furnace System is most suitable and is specially designed for such type of

application keeping in view the site challenges. Environment being harsh and also ambient temperature being

high we suggest air & water cooling for safety purpose and long life of the system.

Key Features

- Wide angle of view 85°

- Relay alarm outputs for DCS.

- Clear live video in low/high light condition.

- Working in harsh and high ambient conditions.

- Rodless cylinder reduce size and weight of system.

- Two Stage air filtration system for clear view and smooth working of system.

- 600mm Stroke useful in wall thickness of 400mm and 800mm Stroke in wall thickness of 600mm.

Results and Conclusion:

The High Temperature Furnace Monitoring System is the most cost effective solution for monitoring of burners,

billets, slabs, rounds, ingots inside Reheating Furnace. Moreover it requires minimum maintenance from the

operator part to run the equipment. Also water cooling helps to reduce the cost of Air Consumption. Only one

analog signal cable required from site Control Panel to CCR.

Finally TFV-1100 is the best solution for the Steel Reheating Furnaces.