Silicon Rubber Heater

Famously known as “flexible heaters”, silicone rubber heaters are composed of fibreglass reinforced silicone rubbers that are rugged, moisture and chemical resistant, flame retardant, have high dielectric strength and are non-toxic. Wire or etched foil heating circuits are positioned between two “wafers” of silicone which provides flexibility and strength.

With silicone rubber heaters, heat can be placed where it is needed. These heaters improve heat transfer, speed warm-ups and decrease wattage requirements. Fibreglass reinforced silicone rubber gives the heater dimensional stability without sacrificing flexibility. Because very little material separates the element from the part, heat transfer is rapid and efficient. The heater construction creates a very thin heater allowing it to fit applications where space is limited.

Silicon Rubber heaters are available in two types

- Wire Wound

- Etched Foiled

- Maximum Size

Length : 1″ to 120″

- Width

1 to 36 inches

- Thickness

0.056″ standard, other thicknesses available

- Voltage

12V to 600V AC or DC

- Maximum Operating Temperature

450°F

- Electrical Rating (Wire)

±10% ,-5 %, foil ±10 %, -10%

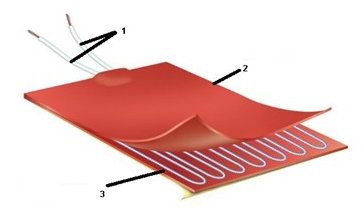

Construction

1. The lead wire consists of high-temperature resistance wire wound around a fibreglass core for added support and flexibility

1. The lead wire consists of high-temperature resistance wire wound around a fibreglass core for added support and flexibility

2. Silicone rubber is rugged, moisture and chemical resistant, flame retardant, have high dielectric strength.

3. Nickel Chromium Resistance wire for maximum life, evenly wound for even heat distribution. The vulcanization process is used to attach the power leads and cord sets to the heater winding.

| Design Options |

|||

| Ground Mesh

For grounding purposes, the second layer of insulating material and a conductive grid can be added to the heater. The heater comes with a ground wire.

|

Sponge Insulation

To improve heater efficiency, 1/16”, 1/8”, 1/4”, 3/8” or 1/2” insulation can be bonded to the outside of the heater. Closed-cell silicone sponge is extremely flexible and has a Temperature range of “-75°C to 250°C”

|

Enclosure Heaters

They are used to maintain the temperature in any type of electrical box. Typical applications include ATM’s, control boxes, traffic signals, utility boxes, cabinets and switchgear. Enclosure heaters are excellent for controlling humidity or moisture within an electrical box.

|

Round Heaters

Round shapes are also available. Round heaters are best attached to tooling with PSA.

|

Mounting Methods

- Pressure Sensitive Adhesive

- Factory Vulcanizing

- Field Applied Adhesive