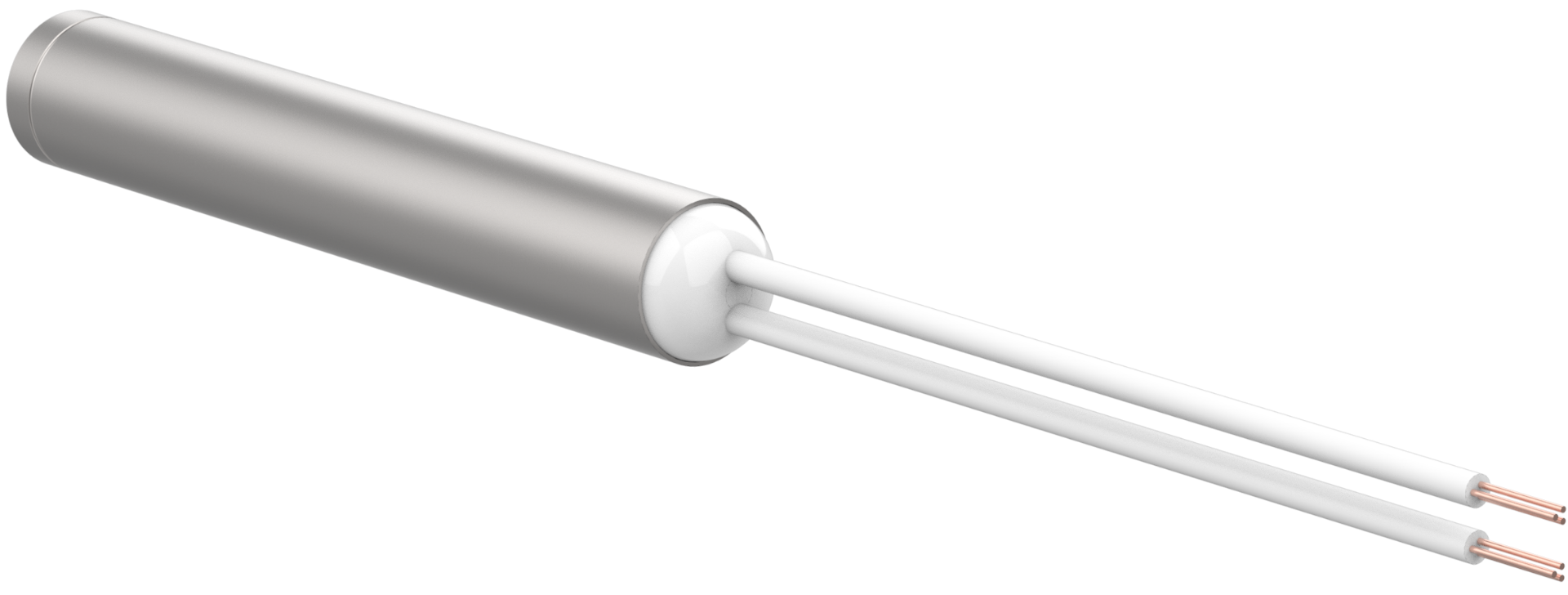

Heater Cartridge

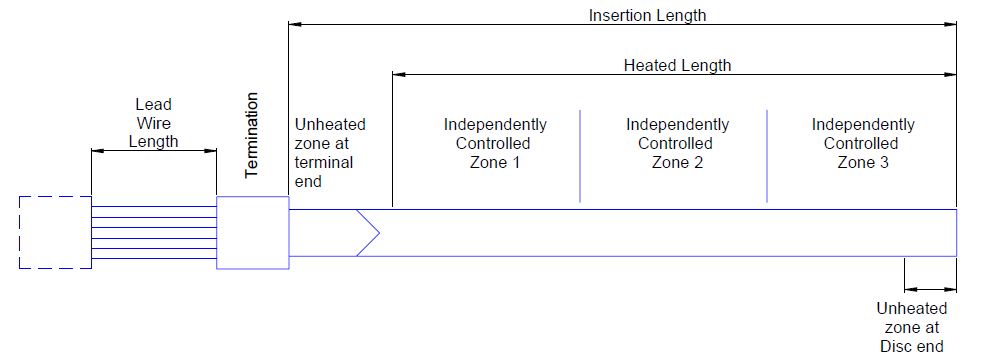

Hot Rod Cartridge Heaters are designed to provide uniform heating and excellent heat transfer rate throughout the heating surface. Facilitated with individually controllable heating zones, various process requirements such as zone specific heating and distributed wattage requirement can be achieved with precise and uniform temperatures. Heaters are constructed with minimal spacing between sheath and heating element to maintain lower internal temperatures which results in smaller sized heaters operating at higher watt densities.

Constructed of high grade Nickle Chromium resistance wire wounded on specially designed cores, separated from metal sheath using high purity magnesium oxide fill, all centered and tightly compacted in SS/Inconel tubing through refined swaging process, results in heaters with minimal air gap, high resistance to corrosion and oxidation, and increased life which makes Marathon make cartridge heaters best in class with high performance and longer durability.

Application Areas

- Semiconductor chamber heating

- Semiconductor wire and die bonding

- Freeze protection and deicing of equipment in cold climates or applications

- Humidity control

- Patient comfort heating used in medical devices

- Metal die casting

- Seal bars used in packaging equipment

- High temperature glass forming equipment

- Sheath Material

Stainless steel, INCOLOY

- Operating Temperature

Up to 760°C

- Watt Densities

Up to 400 W/in2

- Voltage

Up to 480V AC

- Sheath Length Tolerance

±3%

- Wattage Tolerance

+5%, -10%

- Resistance Tolerance

+10%, -5%

- Termination Style

Swaged in leads, Crimped on leads, Right angle leads, Swaged in stainless steel braid etc.

Construction

1.High-Temperature Lead Wires for temperatures up to 550° C

2. High Impact Ceramic Cap retards contamination and is suitable for high vibration applications. Deep holes in cap prevent fraying of lead when bent.

3. Nickel Chromium Resistance wire for maximum life, evenly wound for even heat distribution.

4. High Purity magnesium oxide fill selected for maximum dielectric strength and thermal conductivity, highly compacted for maximum heat transfer.

5. Stainless steel sheath / Inconel sheath for oxidation and corrosion resistance in a wide variety of environment.

6.Tig welded end disc to prevent contamination and moisture absorption

| Termination Options | ||

| Ceramic Bead

When the temperature at the exit of the heater exceeds 590°C, ceramic beads protect the wire until conventional insulation can be utilized.

|

Copper Elbow Flexible SS Conduit

Right angle flexible conduit can also be attached with a copper elbow. This method can also be used to attach right angle flexible conduit to stock heaters.

|

Crimped on leads

Crimp on leads are generally used where the temperature at the end of the heater exceeds the maximum allowable temperature of the lead wire.

|

| Right Angle Leads

Right angle leads are ideal for application with tight spaces. Leads are covered with a silicon impregnated fibreglass sleeve where they exit the heater.

|

Right Angle SS Flexible Conduit

It offers the same advantage as that of stainless steel flexible conduit but right angle arrangement allows it to be used in tight spaces.

|

Sleeving

Silicon Rubber Fiber Glass Sleeving and Fiber glass sleeving

|

| SS Flexible Conduit

Flexible conduit provides maximum protection to leads from abrasion but cannot bend as sharply as stainless steel braid. Flexible conduits are also swaged in, thus provide the same benefit of not being pulled out of the heater.

|

||

| End Seal Options | ||

| Teflon Seal

Teflon seal is used where effective sealing is required against moisture and oil contamination. Teflon lead wire is used in conjunction with a Teflon seal to provide an effective barrier.

|

Epoxy Seal

Epoxy potting forms a good moisture seal with more mechanical strength than a silicon rubber seal. Regular Epoxy is rated at 350°F (177°C) and epoxylite is rated at 600°F (316°C).

|

Silicon Rubber Seal

High temperature silicon rubber seal in conjunction with silicon rubber lead wires provides an effective moisture seal up to 400°F (200°C). It is the most impervious seal of all the other moisture seals.

|

| Fitting Options | ||

| Single-Ended NPT Fitting

Fittings are available in brass and stainless steel. Brass fittings are brazed on and stainless steel fittings can be either brazed or welded on.

|

Double Ended NPT Fitting

Double-ended fittings are normally used when it is desirable to mount a box on an immersion heater. Fittings are available in stainless steel and brass.

|

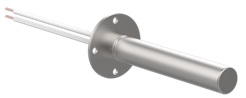

Flanges

Flanges are used to hold heater in place preventing heaters from being backed out during operation. These flanges are welded on the lead end of the heater. They are 1/16” thick.

|

| Other Options | ||

| Post Terminal

Post terminals are used in applications where easy lead replacement is desirable

|

Bent Hot Rod

Heaters can be bent at any angle from 10°C to 120°C. Heaters are bent at the unheated section.Option of bending is available in most of the heaters.

|

Double Ended

Hot rods are also available with electrical termination on each end. Heaters can be made with lead wire, straight pins, or screw terminals.

|

Technical Specifications

| Nominal diameter | Minimum diameter | Maximum diameter | Std. Lead wire gauge | Max amps with std. Lead wire | Max lead wire gauge | Maximum amps | Maximum volts |

| 1/8” | 3.022 | 3.14 | 24 | 3.6 | 24 | 3.6 | 240 |

| 1/4″ | 6.19 | 6.32 | 24 | 6 | 22 | 9 | 300 |

| 6 mm | 5.82 | 5.97 | 24 | 6 | 22 | 9 | 300 |

| 6.5 mm | 6.35 | 6.47 | 24 | 6 | 22 | 9 | 300 |

| 5/16” | 7.77 | 7.89 | 24 | 6 | 22 | 9 | 300 |

| 8 mm | 7.84 | 7.97 | 24 | 6 | 22 | 9 | 480 |

| 3/8“ | 9.37 | 9.49 | 22 | 9 | 18 | 15 | 480 |

| 10 mm | 9.86 | 11.96 | 22 | 9 | 18 | 15 | 480 |

| 12 mm | 11.83 | 12.48 | 22 | 9 | 18 | 15 | 480 |

| 12.5 mm | 12.34 | 12.67 | 22 | 9 | 18 | 15 | 480 |

| 1/2″ | 12.55 | 12.97 | 22 | 9 | 18 | 15 | 480 |

| 13 mm | 12.85 | 13.46 | 22 | 9 | 18 | 15 | 480 |

| 17/32” | 13.33 | 15.84 | 22 | 9 | 18 | 15 | 480 |

| 14 mm | 13.84 | 13.97 | 18 | 15 | 14 | 26 | 480 |

| 5/8” | 15.72 | 15.84 | 18 | 15 | 14 | 26 | 480 |