Substation Monitoring System

A Typical substation (Switch Yard) consists of CT ( Current Transformer), PT ( Power Transformer), CB ( Circuit Breakers), Surge or Lightning Arrester, Busbars, Earth Connectors, Potential Transformer etc. These components are connected that form “joints”. Normally, over the period of time, these joints develop hot-spots which require timely and daily monitoring. These hot spots may cause breakdown of the sub station which may result in shutdown of plants which is dependent on power from the substation. It may also cause accident

So, it is important to monitor “host spots” in a substation regularly to prevent such breakdown or accidents.

ACCUOPT DCTMS-640 : Substation Monitoring System detects hot-spots in switch-yard or substation, prepares reports against every potential host-spots in “joints”, keep a record for analysis and displays them in control room.

DCTMS-640 helps preventive maintenance of your switch-yard/substation

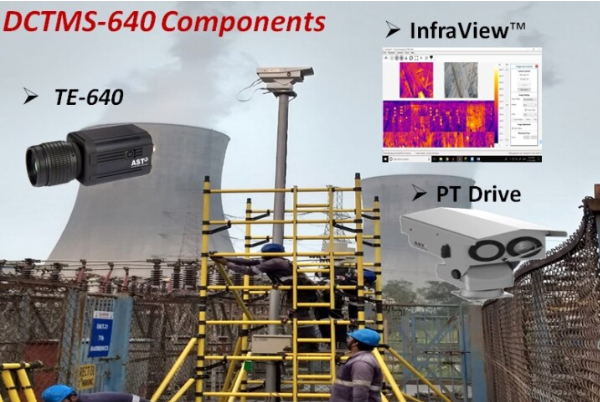

Key Components of DCTMS-640

- LTE-640 : Its a high resolution ( 640X480Pixels) thermal camera which is the core of the DCTMS-640 Substation Monitoring System. It uses a lens which is selected as per desired area to measure hot-spots in the switch-yard or substation.

- 2MP Visual Camera : Visual Camera is used for better identification of the joints manually during the hot-spot location during installation from control room or during any manual inspection remotely from control room.

- PT-Drive with Enclosure : This is a PAN and TILT System which helps the DCTMS-640 cover more areas per unit. Its a weather proof military grade system designed to perform in harsh weather conditions.

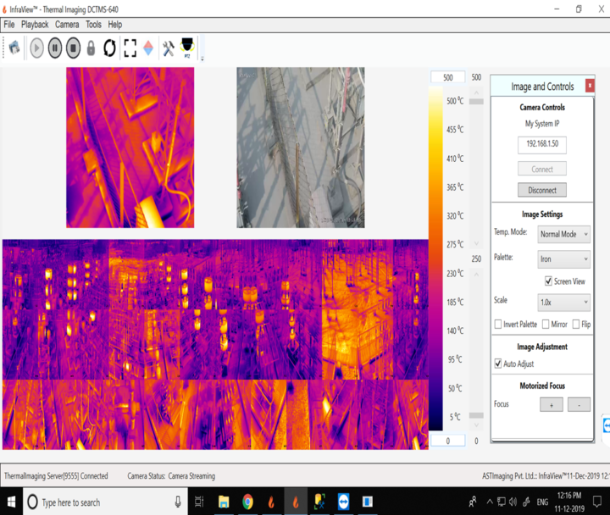

- INFRAVIEW Software : This is an WIndows Based Thermal Image Acquisition and processing software which detects hot-spot , generates reports automatically once or twice a day. The period can be configured. This software is heart and mind of the DCTMS-640 Substation Monitoring System solution. INFRAVIEW Software has many features which are useful for switchyard monitoring system.Humidity control

Apart from above main components, a panel box that houses all power supplies, ( network equipment if any) are kept at the location near to the installation of the DCTMS-640. Also, it is normally mounted on a rugged pole at approx 45 degree angle to cover large area of the switch-yard or substation.

Normally, at least 1GBPS data link is required from the DCTMS-640 installation site to the control room where a Server Grade PC is located with INFRAVIEW Software. If continuous monitor is not needed, than multiple ( upto 8) units of DCTMS-640 can be connected to the same data link as well as the same PC.