Hot Rolling Mill and brief process of Hot Rolling Mill

The rolling is metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. Rolling is classified according to the temperature of the metal rolled. The temperature of the metal is above its recrystallization temperature, this process is known as Hot Rolling

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains a microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semi-finished casting products, such as slabs, blooms, and billets. If these products came from a continuous casting operation the products are usually fed directly into the rolling mills at the proper temperature. In smaller operations, the material starts at room temperature and must be heated. This is done in a gas/oil-fired soaking pit for larger work pieces; for smaller work pieces, induction heating is used. As the material is worked, the temperature must be monitored to make sure it remains above the recrystallization temperature. To maintain a safety factor a finishing temperature is defined above the recrystallization temperature; this is usually 50 to 100 °C (90 to 180 °F) above the recrystallization temperature. If the temperature does drop below this temperature the material must be reheated before hotter rolling.

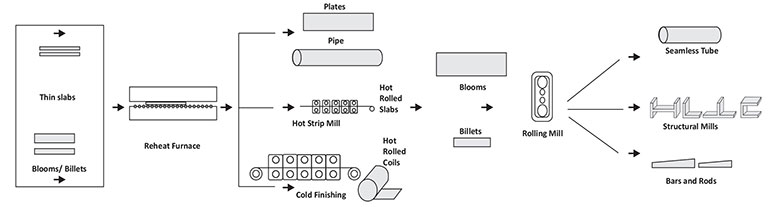

Hot Rolling Mill Process Diagram

Need of temperature measurement or control in Hot Rolling Mill

The Hot Rolling Mill is used to reheat shapes of steel to soften them enough so that they can be rolled thinner and longer through a series of rolling stands. The finished product can be either a strip, plate, rod, bar, wire, or shape (rails and H-beams). After the steel is formed to its desired shape, it is cooled so that the desired mechanical properties of the steel product are achieved.

Temperature control is critical throughout the Hot Rolling Mill to assure desired product properties, ensure quality product, improve line speed and process control. There are a number of interferences that can affect the pyrometer reading at every point along the hot rolling mill. These include water, steam, scale, misalignment, and emissivity variation. Wavelength selection is a critical choice in helping to minimize or eliminating the temperature errors due to these interferences. The process temperature is approximately 1000°C to 1200°C

As the object is moving in semi-solid state we can’t use thermocouples (contact type temperature sensor) here as it will harm the semi-solid material and also there is a chance of sensor getting damaged due to the motion.

Here comes the need of non-contact temperature sensor and as pyrometer works in IR principle, it provides the much needed solution. Pyrometers also feature extremely fast response speeds of a few milliseconds. This makes them very useful for temperature measurement of fast-moving strip or rod. The main advantage of using pyrometer, you can automate the complete process. If the complete process is automated this will increase the product quality and increase the productivity. The pyrometer has very low maintenance cost against thermocouple maintenance cost. In complete process at two stages pyrometer is required. First, after hot rolling and second after quenching. The both location is very critical because, these two stages define the quality and productivity of product

Site Challenges in Hot Rolling Mill

The temperature of hot rolling is around 1000°C to 1300°C. The hot rolling mill having a challenging environment for making any kind of temperature measurements like high temperature and the movement of the metal, make thermocouples and other contact temperature sensors impractical. The main two challenges are as below:

- The environment is very harsh.

- The site ambient temperature is very high up to 70°C or 80°C.

What we offer

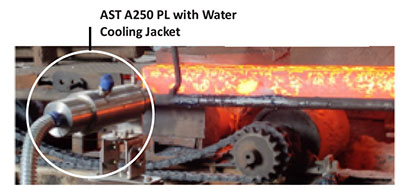

The AST A250 PL is most suitable and specially designed pyrometer such type of applications. Environment being harsh and also high ambient temperature, we suggest water cooling for safety and long life of pyrometer. This AST A250 PL and accessories has the following features:

- Very fast response time with in mille seconds and adjustable as required and wide temperature range (210- 3000°C).

- BluetoothCommunication for parameterization, you can connect pyrometer with your android mobile and change parameters remotely.

- Supplied with water cooling jacket and junction box for smooth process and safety of instrument.

- User selectable Analog output for automation of process.

- Laser or through the sighting options are available. (As per customer requirement)

- With Software it can easily be connected to a local PC/System, which will give runtime temperatures and graphical trend also.

Hot Rolling of Billet