Furnaces of high temperature are commonly used in thermal industries and laboratory purposes.

So, now we are talking about the most efficient and uniform Bottom loading furnace. The things are in our mind is what is bottom loading furnace? What is its working? What are its applications? So, don’t worry we discuss step by step in this blog post.

So let’s first start with its basics

What is bottom loading furnace ?

Bottom loading is high temperature furnaces ideal and very convenient for large, heavy or high volume workloads, specially good and easy for load unload. Loading work from the bottom has the advantage of accommodating load/sample structures which are heavy and large.

So, its convenient for Lifting from bottom or unloading, from the support arm at a comfortable position separate from the furnace. Lifting platform located under the furnace which lifts manually or automatically.

Bottom loading furnaces are designed for uniform thermal distribution inside the chamber, easy loading and unloading of sample with help of lifting arrangement.

They are high temperature uniform batch furnaces with electrical heating element uniformly assemble around the heating chamber with insulation.

Working of bottom loading furnace

- Bottom loading furnace has uniform heat distribution because of uniformly assembled heating element at four side of chamber.

- Stainless Steel: Body made up of SS metal which provides strength to it.

- Heating Elements: Electrical heating elements are responsible for uniform heating in chamber.

- Loading Platform: It is used for lifting weight and parts from the bottom side.

- Electrical Assembly: High power supply connections at bottom side of furnace.

- Thermal Insulation: Thermal insulation to prevent Heat Loss.

- LoadingMechanism: BLF bottom loading furnaces use an electrically operated elevator, which lifts the load into the heated zone.

Advantages

- Easy loading and unloading of sample

- Uniform Temperature distribution inside chamber

- Fast Cooling

- Low heat loss

- Smooth lifting arrangement

Applications

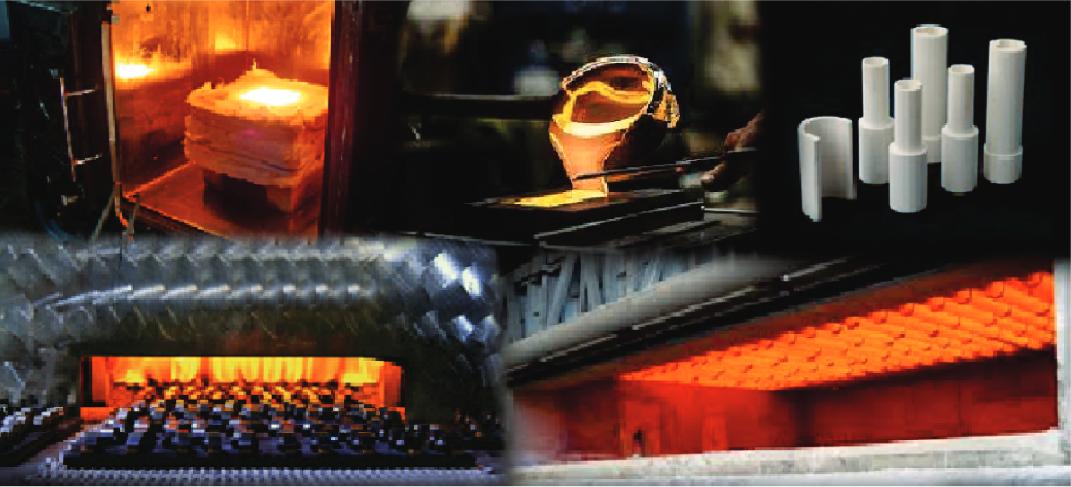

- Melting

- Sintering

- Ferroelectric Applications

- Ceramic Industry

- Heat Treatment

Key Features

- Maximum Temperature : 1800° C.

- Time to reach Maximum Temperature : 1.5Hrs.

- Temperature Uniformity : +/- 5° C

Models

| Model | Max Temp(°C) | Internal Dimension (HXWXD) (mm) |

External Dimension (HXWXD) (mm) |

Controlling Thermocople | Heating Element |

|---|---|---|---|---|---|

| BLF- 1200 | 1200 | 120X120X120 *Customized Chamber size available on request |

1010X600X595 | N | Kanthal A1 |

| BLF-1500 | 1500 | R | Silicon Carbide | ||

| BLF- 1800 | 1800 | B | MoSi2 |